overview

This is an example of how to set up an RS-232C connection with KV-1000.

Model used

item |

Model etc. |

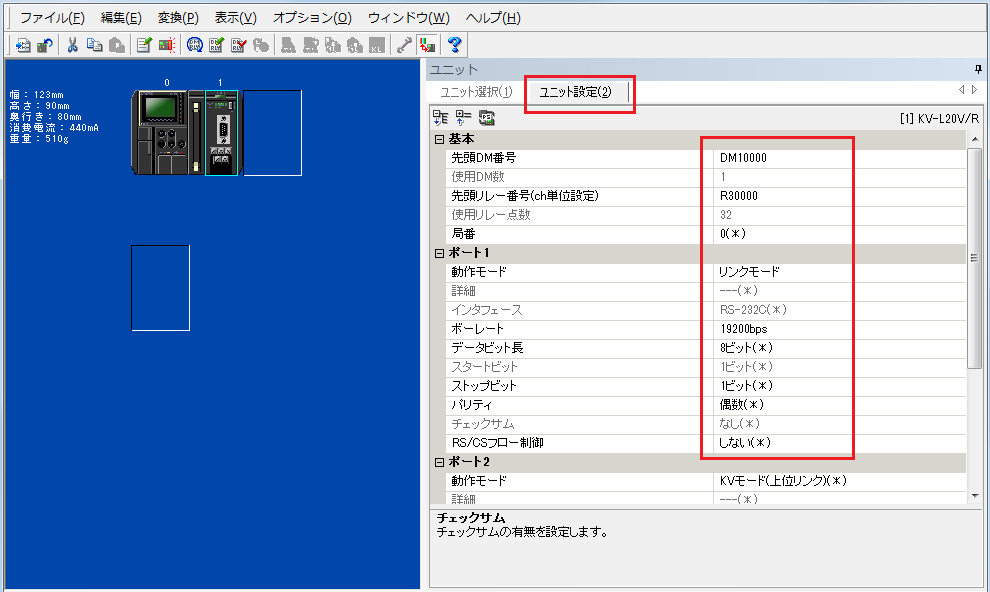

PLC |

KV-1000 |

Communication Unit |

KV-L20R |

Configuration environment

item |

environment |

OS |

Windows7 Professional 64Bit |

OS |

KV STUDIO 6.13 |

Configuration details

item |

setting |

Setting items |

Configuration Example |

PLC side settings |

Set with tools |

Operational Mode |

Link Mode |

baud rate |

19200bps |

||

Data bit length |

8bits |

||

Stop bits |

1bits |

||

parity |

Even |

||

PC settings |

Unit Settings |

COMM |

Communication port number to connect to |

Transmission speed |

19200bps |

||

Byte Size |

8bits |

||

Stop bits |

1bits |

||

parity |

Even |

||

Folder and communication test settings |

Unit No. |

0 |

* Most of the settings on the computer will be adjusted to match the settings on the unit.

PLC side settings

Configure the KV-1000. The configuration is done using KV STUDIO etc.

1.Start KV STUDIO and create a new project

2.Open the menu "Monitor/Simulator" - "Communication Settings" - "Communication Settings" and confirm that communication with PLC is possible.

3.Select the added unit in the workspace's unit configuration and double-click it.

4.From the unit editor, select "File" - "Load unit configuration from PLC" to load configuration information from PLC.

5.Configure the settings as follows, click the "Apply" button, and close the dialog.

setting |

Setting contents |

First DM |

DM10000 (Set the first number of the DM used in the unit) |

First relay number (channel unit setting) |

R30000 (Set the first relay number used in the unit) |

Communication Mode |

Link Mode |

baud rate |

19200bps |

Data bit length |

8-bit |

Stop bits |

1 bit |

parity |

Even |

|

For detailed settings such as the first DM, please refer to the Keyence "Multi Communication Unit KV-L20" user manual.

|

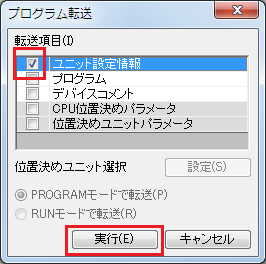

6.From the menu, select "Monitor/Simulator" - "PLC Transfer" to display the program transfer dialog, check the necessary items, and then write the parameters to the PLC.

|

After setting the parameters, you must turn off the power to the PLC once to reflect the settings. Although a remote reset may be possible from the tool, we recommend turning off the power once to ensure that the settings are reflected. |

|

Some settings cannot be transferred in RUN mode, so in that case please transfer them in PROGRAM mode. |

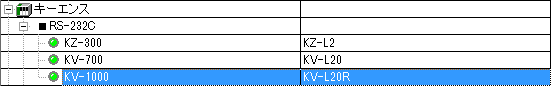

PC settings

Use the Server application to connect to the PLC for which you have set up communications.

1.Right-click "Application" - "Driver" in the tree and select Add Driver.

2.Select the following units from the displayed driver list and add them:

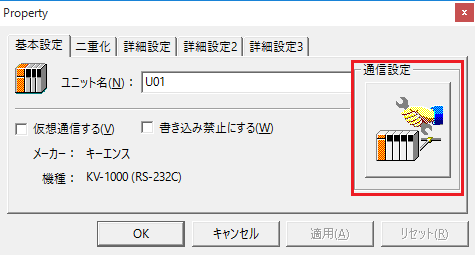

3.Open the properties of the added unit (U01) and click Communication Settings.

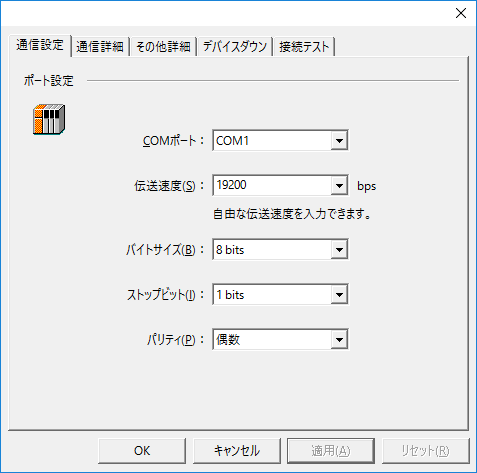

4.Set "Communication Settings" as follows:

setting |

Setting contents |

COMPort |

Communication port number to connect to |

Transmission speed |

19200 |

Byte Size |

8bits |

Stop bits |

1bits |

parity |

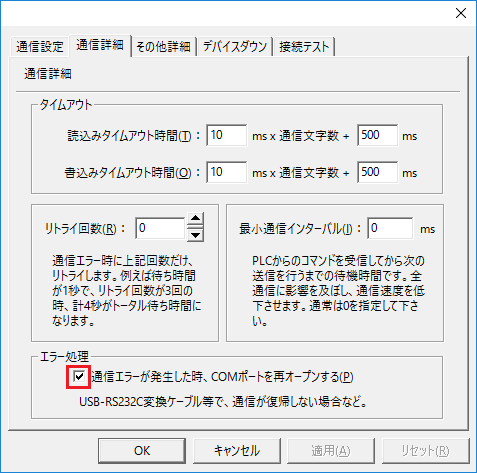

Even |

5.USB-RS-If you are using a 232C conversion cable, the COM port may be locked in the event of a communication error, so check the reopen setting.

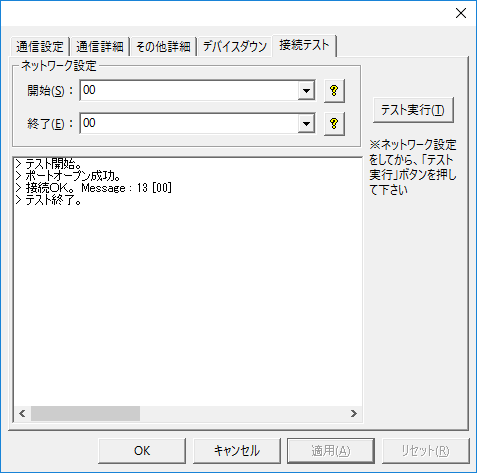

6.Perform a connection test to check the connection

If a message such as "Connection OK" is displayed, the connection is confirmed to be OK.