Static tag and Active tag

When connecting to PLC, it is not necessary to register all tags in advance. By directly specifying the PLC address from the application that uses the tags, it is possible to dynamically establish communication with the PLC without pre-registering tags.

Here, the tag that you register in advance is called "Static tag".

The tag path for Static tag consists of the unit, folder, and tag connected with a period ".".

U01.F01.T01 U01.F01.T02 U01.F01.T03 : : : |

On the other hand, the method of directly specifying the PLC address from a screen, etc., without prior tag registration is called "Active tag".

The tag path of Active tag must have a single “#” character before the address specification.

U01.F01.#D0 *Specify the D0 address of PLC U01.F01.#M0 *Specify the M0 address of PLC : : : |

Static tag and Active tag can be used together.

Depending on how you reference the tag, you may need to specify a parameter string after Active tag. The toolbar will tell you what to specify in the parameter string.

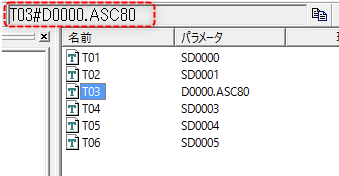

For example, the parameter string for "T03" below is "D0000.ASC80". Therefore, Active tag "U01.F01.#D0000.ASC80" has the same value as Static tag "U01.F01.T03". For details, see "Parameter String".

(Example of a parameter string)

|

With Static tag, it takes time to set tags in advance, but even if the device address of the communication target changes or the PLC model changes, you can make changes by simply changing the tag settings, so there is an advantage that no changes are required to the upper system. In addition, even if there is no connection request or the system is not connected to PLC, you can check the list of tags on the tag list, making debugging easier. If you are unsure whether to use Static tag or Active tag, we recommend using Static tag. |