What is FA-Server?

"FA-Server" is OPC server software developed to build a monitoring system.

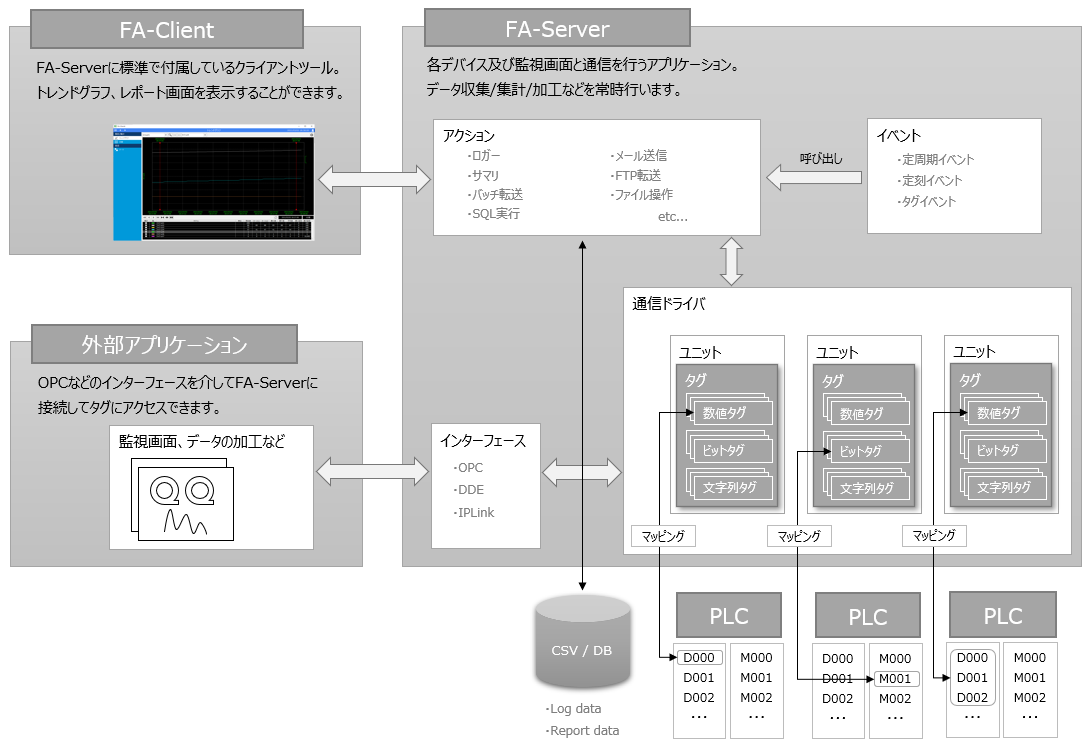

By using FA-Server, it can be used as an "I/O server" for communication with control devices such as PLC. In addition to its function as a simple OPC server, it also has various built-in functions such as data logger, daily report aggregation, FTP transfer, tag bridge (a function that gateways data between PLC), External application execution, SQL call, and script language, allowing you to build various logic on the server side. In addition, FA-Server comes with "FA-Client" as a client tool, which allows you to display trend graphs and Daily/Monthly/Yearly Report on the screen. In other words, it is not just a simple I/O server, but also has the potential to support various functions required for a monitoring system.

Below,FA-ServerHere is a brief introduction to the main features it offers.

Main features of FA-Server

Here we will briefly explain the most representative features provided by FA-Server.

■Communication driver

It is responsible for communication with downstream devices such as PLC and remote I/O. FA-Server comes standard with built-in communication functionality with the equivalent of 100 models of PLC, and can also support system configurations with a mixture of different PLC models if they are compatible. In addition, it supports communication interfaces such as OPC and DDE, and can also link with other companies' OPC server software that complies with the relevant standards. The values of various signals obtained through communication are used by other functions via "tags".

■ Tags

A tag is a data space, like a shared memory, and external applications and various functions that communicate with FA-Server, such as data loggers, can freely access the tags. The PLC device values periodically acquired by the communication driver are always automatically reflected in the tags (upstream). In addition, values written to tags are automatically written to the corresponding PLC device addresses (downstream). Therefore, various functions access the PLC devices via tags.

■ Logging/report aggregation (Daily/Monthly/Yearly Report, etc.)

You can log tag values in FA-Server and automatically aggregate log data as report summary data in Daily/Monthly/Yearly Report, etc. Supported log data formats include text files (CSV) and output to ODBC databases.

■ Client tools (FA-Client)

FA-Server comes with "FA-Client" as a standard client tool. You can use FA-Client to display trend graphs and daily report screens.

■ Other various server logic construction

In addition to logging and report aggregation, many other features are available, such as Send mail, FTP transfer, bridging between tags, External application execution, building logic using scripting languages, calling SQL, etc. Using these features, you can easily achieve a variety of processes on the server side.

|

In addition to standalone operation on a single PC, FA-Server can also be operated as a client-server system using multiple PCs, or can be used for redundancy by duplicating the server. For details on system configuration, please refer to the description in "System Configuration and Operation Mode" in the "System Installation and Operation" chapter. |

|

From version 6 onwards, FA-Engine has been integrated into the FA-Server package.FA-Engine is a ActiveX format library for handling PLC data in development environments such as VisualBasic. The ActiceX library of FA-Engine has a built-in communication driver required for connecting to PLC, and the library itself performs the communication. Therefore, there is no need to run a special application for communication other than the application you create, and you can read and write PLC device values from the application. If you want to access PLC from an application developed with VisualBasic, you can also configure it using FA-Engine.For matters concerning FA-Engine, please refer to the FA-Engine manual. |