Communication setting method

There are two connection points:

•Selecting the right RS-232C cable

There are several types of

RS-232C cables, depending on the number of pins or the wiring method, etc. It is necessary to select a cable by checking the exact number of pins on the PC side and the PLC side, as well as the internal wiring published by the manufacturer.

For more information, refer to the manual for your PLC device.

•Match the communication parameters of RS-232C

The communication parameters on the

PLC side and the PC side must match. The PLC side settings are made using physical DIP switches or configuration software, and the PC side settings are made in the "Communication Settings" dialog of each unit's properties.

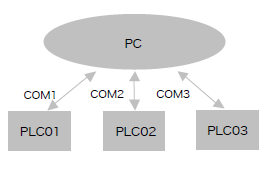

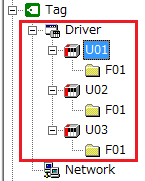

In addition, there are two cases when connecting to multiple PLCs:

|

Communication is carried out by dividing it into multiple ports. Each PLC communicates independently.

|

|

|

|

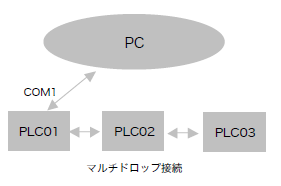

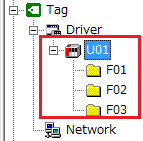

PLC are connected via multi-drop with RS-422. However, the PLC must support multi-drop connections. The PLCs are differentiated by folder network settings, and communication is also performed in order for each folder.

|

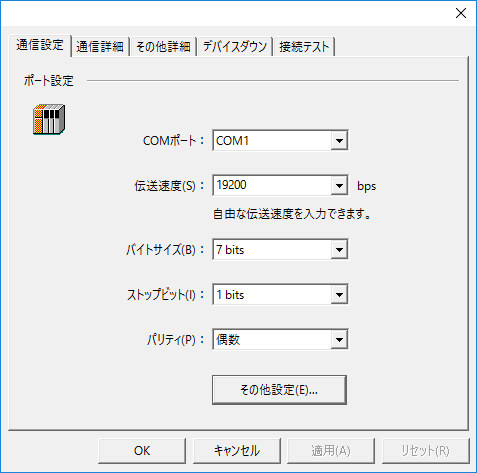

RS-232C common settings dialog

Communication Settings

|

•COMPort

•Transmission speed

•Byte Size

•Stop bits

•parity

•Other settings

|

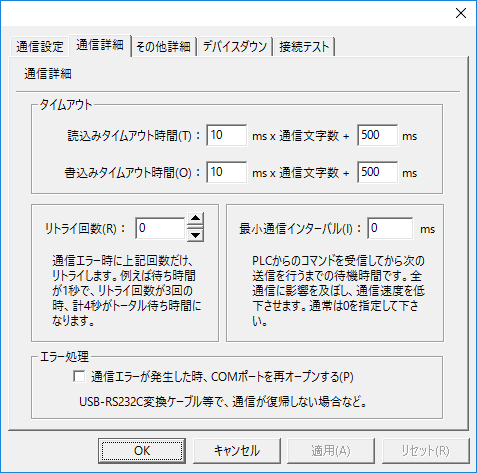

Communication details

|

•Read timeout setting

•Write timeout setting

•Retry count

•Minimum Communication Interval

•Error Handling |