overview

This is a setting example for connecting to the iQ-R series via RS-232C. The iQ-R series cannot be configured with GX-Developer, so GX-Works3 is used.

Model used

item |

Model etc. |

PLC |

R08CPU |

Communication Unit |

RJ71C24 |

Configuration environment

item |

environment |

OS |

Windows8 Professional 64Bit |

tool |

GX-Works3 Ver1.000A |

Configuration details

item |

setting |

Setting items |

Configuration Example |

PLC side settings |

Set with tools |

Communication protocol settings |

MC Protocol (Format 1) |

Communication speed settings |

19200bps |

||

Operational Settings |

Independence |

||

Data bits |

7 |

||

Parity Bit |

can be |

||

Odd/Even Parity |

Even |

||

Stop bits |

1 |

||

Sum Check Code |

can be |

||

RUN Writing |

permission |

||

Station number setting |

0 |

||

PC settings |

Unit Settings |

COMPort |

Communication port number to connect to |

Transmission speed |

19200bps |

||

Byte Size |

7bits |

||

Stop bits |

1bits |

||

parity |

Even |

||

Sum Check |

can be |

||

protocol |

Format 1 |

||

Folder and communication test settings |

Area code |

0 |

|

Network Number |

0 |

||

PC Number |

FF |

||

Request unit I/O number |

3FF |

||

Request destination unit station number |

0 |

||

Your number |

0 |

* Most of the settings on the computer will be adjusted to match the settings on the unit.

PLC side settings

Set to "R08CPU". Settings are done using GX-Works3 etc.

1.Start GX- Works3 and create a new project.

2.Open the menu "Online" - "Connection Destination" and confirm that you can communicate with PLC.

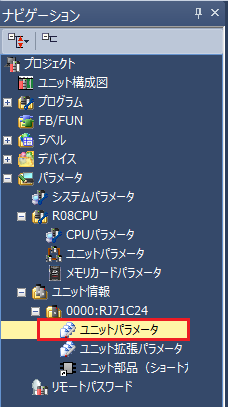

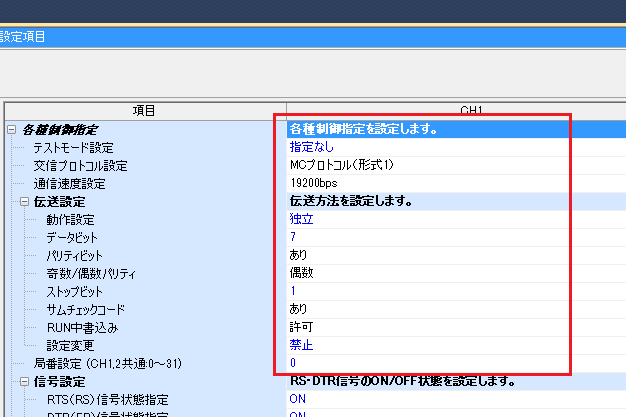

3.Double-click "Parameter" - "Unit Information" - "Name of the unit to be connected (R08CPU in this example)" - "Unit Parameters" in the navigation tree and set the parameters as follows:

setting |

Setting contents |

Communication protocol settings |

MC Protocol (Format 1) |

Communication speed settings |

19200bps |

Operational Settings |

Independence |

Data bits |

7 |

Parity Bit |

can be |

Odd/Even Parity |

Even |

Stop bits |

1 |

Sum Check Code |

can be |

RUN Writing |

permission |

Change settings |

Prohibited |

Station number setting |

0 |

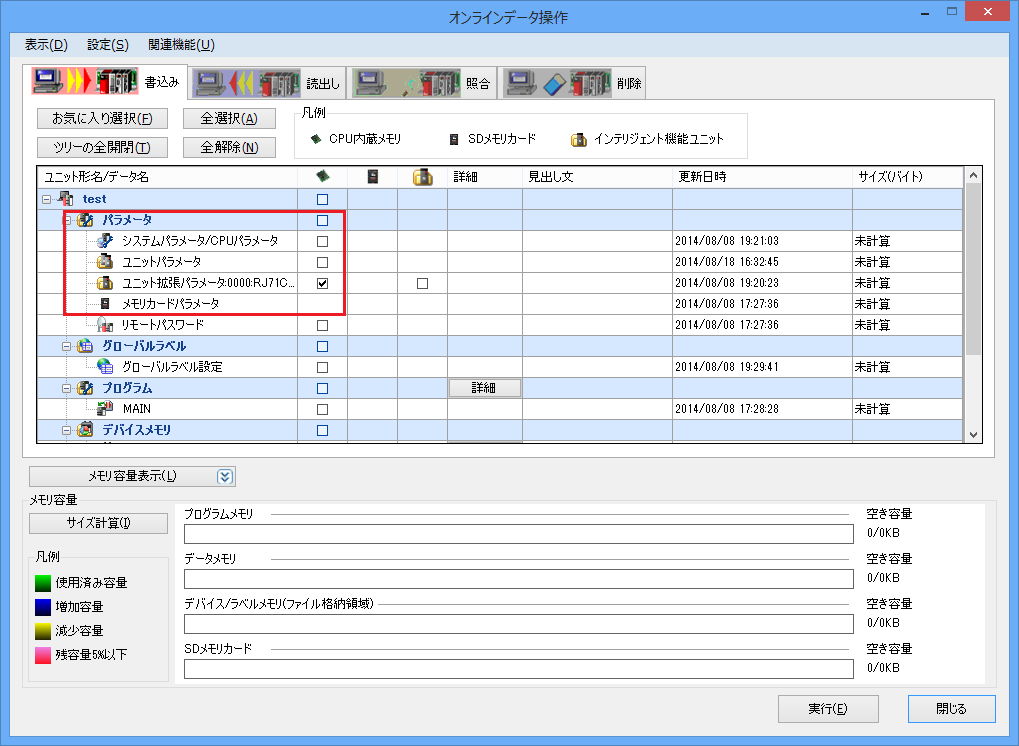

4.Write the parameters to the PLC by selecting "Online" - "Write to PLC" from the menu.

|

After setting the parameters, you must turn off the power to the PLC once to reflect the settings. Although a remote reset may be possible from the tool, we recommend turning off the power once to ensure that the settings are reflected. |

PC settings

Use the Server application to connect to the PLC for which you have set up communications.

1.Right-click "Application" - "Driver" in the tree and select Add Driver.

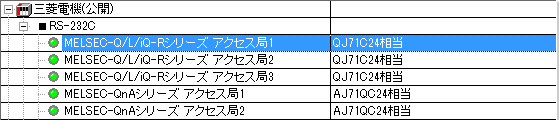

2.Select the following units from the displayed driver list and add them:

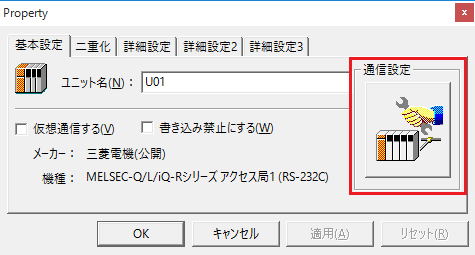

3.Open the properties of the added unit (U01) and click Communication Settings.

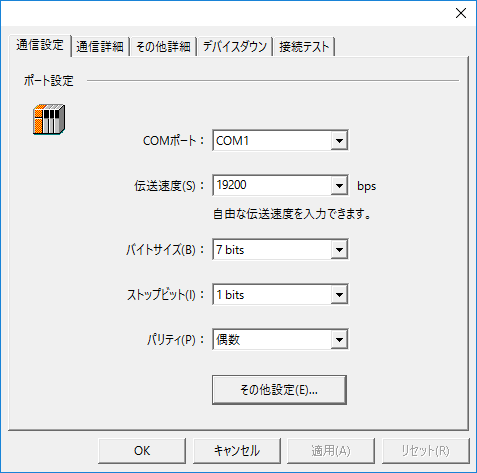

4.Set "Communication Settings" as follows:

setting |

Setting contents |

COMPort |

Communication port number to connect to |

Transmission speed |

19200 |

Byte Size |

7bits |

Stop bits |

1bits |

parity |

Even |

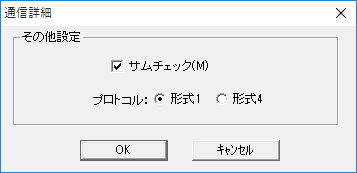

5.Open "Other settings" and set it as follows:

setting |

Setting contents |

Sum Check |

Check it |

protocol |

Format 1 |

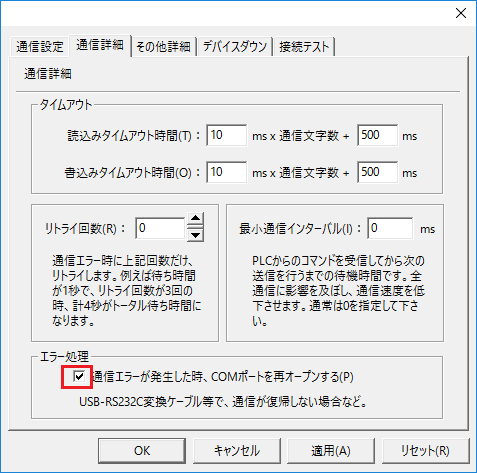

6.USB-RS-If you are using a 232C conversion cable, the COM port may be locked in the event of a communication error, so check the reopen setting.

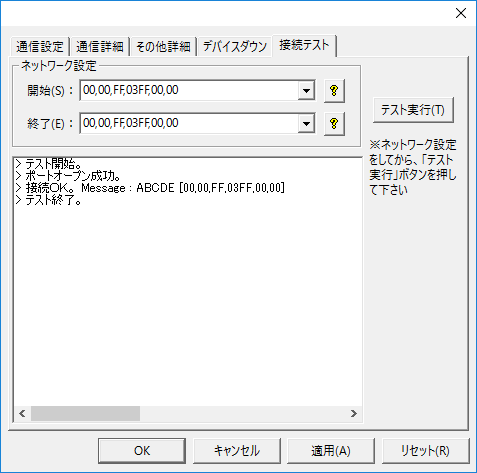

7.Perform a connection test to check the connection

If a message such as "Connection OK" is displayed, the connection is confirmed to be OK.